We specialize in providing comprehensive solutions from consulting, surveying, designing, supplying equipment and materials to construction and installation, warranty and maintenance for solar projects in Vietnam.

Solar Project in Dak Lak

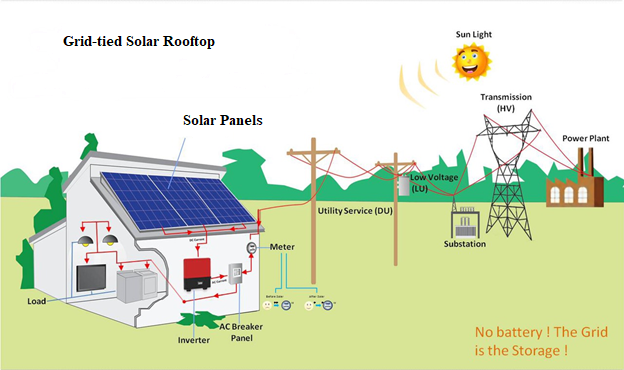

Installing the panels Grid-connected solar power system solution

1.1. The operating principle of the system – Solar battery system will receive solar radiation and convert into a direct current (DC). DC will be converted by an inverter and become alternating current (AC) and join the power grid to supply the load.- Grid-connected inverter has built-in maximum power point detector (MPPT) to make the most of the electricity generated from solar panels. In addition, the grid inverter also has a current detector, voltage and phase of the grid to synchronize solar power with the power grid.

– Solar battery system will receive solar radiation and convert into a direct current (DC). DC will be converted by an inverter and become alternating current (AC) and join the power grid to supply the load.- Grid-connected inverter has built-in maximum power point detector (MPPT) to make the most of the electricity generated from solar panels. In addition, the grid inverter also has a current detector, voltage and phase of the grid to synchronize solar power with the power grid.

The system works in three cases as follows:

• Case 1: When the generated capacity is larger than the consumed load capacity, the power will be return to the grid by the system. On the other hand, if the generated capacity is less than the demand then the grid will automatically compensate to supply the demand load.

• Case 2: when it is sunny and the power is out, the system will also stop working to ensure safety (Islanding protect function).

• Case 3: The system only works during the day (when there’s sunshine) so at night the system will hibernate and automatically restart again the next morning.

1.2. Surveillance communication

All power generated data and operating status of the system will be transferred by WIFI200 communication device (for wireless network), ENET200 (for wired network), GPRS200 (for transmission via mobile network data) are exchanged and transfer to Cloud for storage daily, monthly and yearly.

Communication solutions can help operators monitor the system by phone, computer and tablet … through the internet.Communication solutions will also help suppliers to monitor the system and support the customers at the right time.

2. Installing the panels.

Analysis of roof surface

Analysis of roof surface

2.1. Frame construction

– Roof area 1, 2, 3 with frame constructed from aluminum rail, installed close to the roof with a tilt of 90 0- The battery platform is installed with a specialized aluminum frame with the following equipment:

+ Aluminum rail (4) and connecting devices (1)+ Middle Pad (2) and End Pad (3).

+ L-shaped support linked leg and purlin with Rail (5). Details of SOLAR sheet and roof

Details of SOLAR sheet and roof

3. Power system solution

– Construction of R&D factory electrical system: Inverter and electrical cabinets are installed on the wall in R&D workshop. The DC cable that goes from the battery platform to the inverter is protected in an iron cable tray.

– Construction of KTCLSP factory electrical system: Inverter and electrical cabinets are installed on the wall in the factory. The DC cable that goes from the battery platform to the inverter is protected in an iron cable tray.

– Construction of Military Medical electrical system: Inverter and electrical cabinets are installed on the wall of Military Medical building. The DC cable that goes from the battery platform to the inverter is protected in an iron cable tray.

– Construction of electrical systems of executive buildings: Electrical cabinets and inverters are installed on the rooftop. The AC cable connects follows the available cable tray and connect to the main floor switchboard.

4. Specifications of equipment used in the system

4.1. Solar panels

|

Electrical part specifications | |

| CapacityMax (Pmax): | 385Wp | |

| Operating voltage (Vmpp): | 37.8 V | |

| Operating current (Impp): | 9.13A | |

| Open circuit voltage (Voc): | 46 V | |

| Operating current (Isc): | 9.69A | |

| Efficiency module: | 17.74% | |

| Parameters affected by temperature | ||

| Power attenuation factor: | -0.39%/0C | |

| Voltage attenuation coefficient: | -0.29%/0C | |

| Current attenuation coefficient: | 0.005%/0C | |

| Mechanical specifications | ||

| Cell type: | Poly-Percium | |

| Number of cell: | 72 | |

| Number of bypass diode: | 3 | |

| The panels are designed and tested according to international standards for quality (IEC 61215) and safety standards (IEC 61730, UL 1730). | Size: | 1960x992x35 mm |

| Mass: | 22.4 | |

| Tempered glass thickness: | 3.2mm | |

| Connection port | T4 |

4.2. Grid inverter

|

DC power input | |

| Capacity max (W): | 26000 | |

| Voltage max (V): | 1000 | |

| Starting voltage (V): | 220 | |

| Operating voltage range (V) | 180 – 800/610 | |

| Optimal operating voltage range (V): | 400 – 800 | |

| The number of MPPT | 2 | |

| Current per MPPT (A) | 30 | |

| AC power output | ||

| Output power (W): | 25000 | |

| Max current (A):: | 40 | |

| Operating voltage range (V): | 230/400 | |

| Operating frequency range (Hz): | 50Hz – 60Hz | |

| Harmonic distortion | <3% | |

| Power factor | 98.3% | |

| The inverter is designed and tested according to international standards such as operating environment conditions (IECu 60068), performance testing (IEC 61683), Grid connection standard (IEC 61727), level test electromagnetic compatibility (IEC 61000), Compliance with safety and protection standards (IEC 62109, IEC 62116: 2014). | System parameters | |

| Maximum performance | 98.3% | |

| Efficiency MPPT | 99.9% | |

| Cooling | Fan speed regulator | |

| Standard protection | IP65 | |

| Working temperature | -250C ~ +600C | |

| Noise level | <50dB | |

| Size | 480x610x204 |

|

DC power input | |

| Max power (W): | 54300 | |

| Max voltage (V): | 1100 | |

| Starting voltage (V): | 200 | |

| Operating voltage range (V) | 280 ~ 850/610 | |

| Optimal operating voltage range (V): | 550 ~ 850 | |

| The number of MPPT | 2 | |

| Current per MPPT (A) | 75 | |

| AC power output | ||

| Output power (W): | 50000 | |

| Max current (A): | 72.5 | |

| Operating voltage range (V): | 310 ~ 480V | |

| Operating frequency range (Hz): | 50Hz – 60Hz | |

| Harmonic distortion | <3% | |

| Power factor | -0.8~+0.8 | |

| The inverter is designed and tested according to international standards such as operating environment conditions (IEC 60068), performance tests (IEC 61683), | System parameters | |

| Maximum performance | 98.9% | |

| MPPT performance | 99.9% | |

| Grid connection standards (IEC 61727), level test electromagnetic compatibility (IEC 61000), Compliance with safety and protection standards (IEC 62109, IEC 62116: 2014). | Cooling | Quạt điều tốc |

| Standard protection | IP65 | |

| Working temperature | -250C ~ +600C | |

| Noise level | <50dB | |

| Size (HxWxD) | 810x645x235 |

4.3 Electrical cabinet

| Junction box:

|

Manufacturer: Hensel (Germany)

Protection level: IP67 Resistant to UV, Rain, sea salt, Protection against fire Standard: IEC 60670-22 Material: PC-GFS plastic (Polycabonate) |

| Switchboard, switch protection:

|

Manufacturer: DAT (Vietnam)

Electrical cabinets, made of steel, powder coated with waterproof rubber seals that spill inwards. Can be appropriately designed for outdoor or indoor installation.

|

4.4. Wire

PV-1F cable:: |

Manufacturer: Baohing (China)

Protective shell: XLPE, Insulation class: XLPE Standard: TUV 2 PfG 1169/082017, UL4703 Operating voltage: 1000VDC Working temperature: 900C |

| Cable CXV:

|

Manufacturer: Lion (Korea)

Protective shell: PVC, Insulation: XLPE Standard: IEC 60502 Operating voltage: 600 / 1000VAC Working temperature: 900C |